Casco Bay Molding works closely with customers/development partners to deliver well-designed, cost-effective products and components. We are a certified, liquid silicone silicone product customization and plastics product development and manufacturing company. We specialize in high-volume injection molding of custom parts for thermoplastic and liquid silicone products, short-term prototype silicon parts, and overmolded silicone products custom made in plastics and metals.

Product Development: Our team enjoys working with our customers and selected development partners to develop products to meet the needs of our customers. We have the ability to meet your projects, our standards, and guarantee the highest quality. The project includes molding technology challenging and chemical thermoplastics, molding syndiotactic polystyrene, then turnkey production units for ultrasonic welding and inspection of parts.

Product Development: Our team enjoys working with our customers and selected development partners to develop products to meet the needs of our customers. We have the ability to meet your projects, our standards, and guarantee the highest quality. The project includes molding technology challenging and chemical thermoplastics, molding syndiotactic polystyrene, then turnkey production units for ultrasonic welding and inspection of parts.

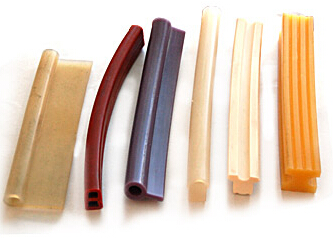

Combine two parts to form a silicone product. Customized manufacturers' application range Overmolding or two-component molding is a great way to reduce assembly costs and improve part quality! Overmolding silicone to plastic, glass, or metal components often achieves this goal. The development cycle of the Casco Bay formed team has gone through many development cycles. Please take a look at what we have seen as a "standard" step to develop new products. We look forward to learning about your products and working with you through this process.

By answering a few questions and uploading a part file, even a rough sketch or photo is a big help to understand your project. We look forward to working with you on developing products! The Casco Bay team likes to develop custom parts for two-component or over-molded silicone products. CBM provides the ability to inject molds into both thermoplastic and silicone silicone products with custom ingredients in one factory, accelerating the product development cycle while avoiding the advantage of "two manufacturers finger pointing". Our team's LSR overmolding/two-component liquid silicone silicone product customization experience includes: Silicone products custom scraper: silicone overmolded to plastic handle, two-component silicone military products, silicone products custom molded to a precision The metal plate is made of diode, food processing part: silicone seal overmolded to a polysulfone base, laboratory utensils using silicone silicone products custom gasket overmolded parts, medical and dental handle silicone overmolding Made into stainless steel tubes, filter applications and molded to plastic screen silicone products with custom gaskets and silicone overmolded to slides.

Over-molded liquid silicone silicone products are custom-tailored for product development cycles by understanding the environment in which customers' applications and components are used. Below, please find out some of the tips of a successful two-component/overmolding project that are designed to understand the capabilities of thermoplastics in processes and materials. The simplest design is the most elegant. Material selection: Working with CBM to define which thermoplastics can handle the heat of an injection mold. Some examples of acceptable thermoplastics are injection molded nylon, syndiotactic polystyrene polycarbonate, and polysulfone. The glass fills the chemical bonds of silicon in the aid version of these resins. Bonded type: The most reliable result is achieved with both mechanical and chemical bonds. Mechanical design is a good part design decision. The chemical bond facilitates treatment with an initiator and/or a surface having a sufficient amount of surface area. Tools: We often let our custom-made silicone and mold engineers participate in the early stages of the process once they receive an order. Care must be taken to address the change in potential in the direction of contraction. Customized production methods for silicone products: High or low volume answers can be determined. High volumes allow for fully automated production with two-component molding machines, while in low volume methods, most commonly, machine operators manually insert plastic or metal parts.

Prototype overmolded parts: If a project is a technical and high-volume, it should respond to customers' investment in single-cavity silicone products for short-term/prototype injection molds. Casco Bay often builds a single chamber at the four-cavity mold base, allowing us to blindly invest in partial designs for single-cavity customers that are tuned before mass production. Manufacturability and Tolerance: Part of the design's real-world tolerances, defining non-critical parts for silicone product customization and plastic controllable and venting. Once the overmolded silicone component is developed and the customer accepts the "design phase tolerance" can be adjusted to meet the end use fit and function of the device. With the approval of our customers and in accordance with our procedures, Casco Bay Forming uses these “production tolerances” as part of the job acceptance criteria. This standard is defined for each job and a part of the "job description," CBM internal file display.